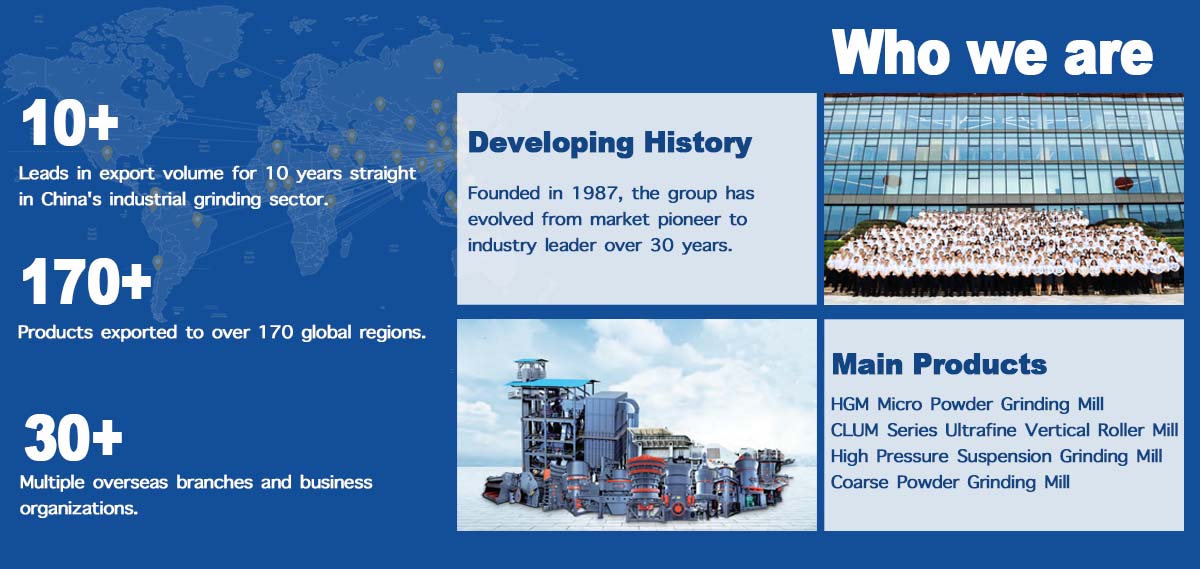

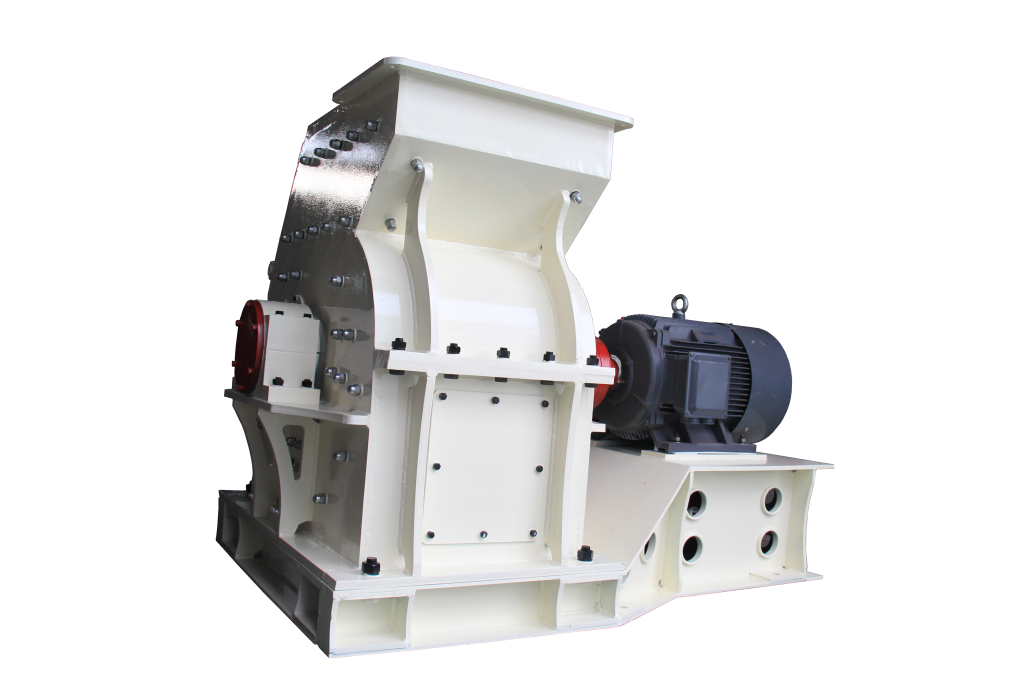

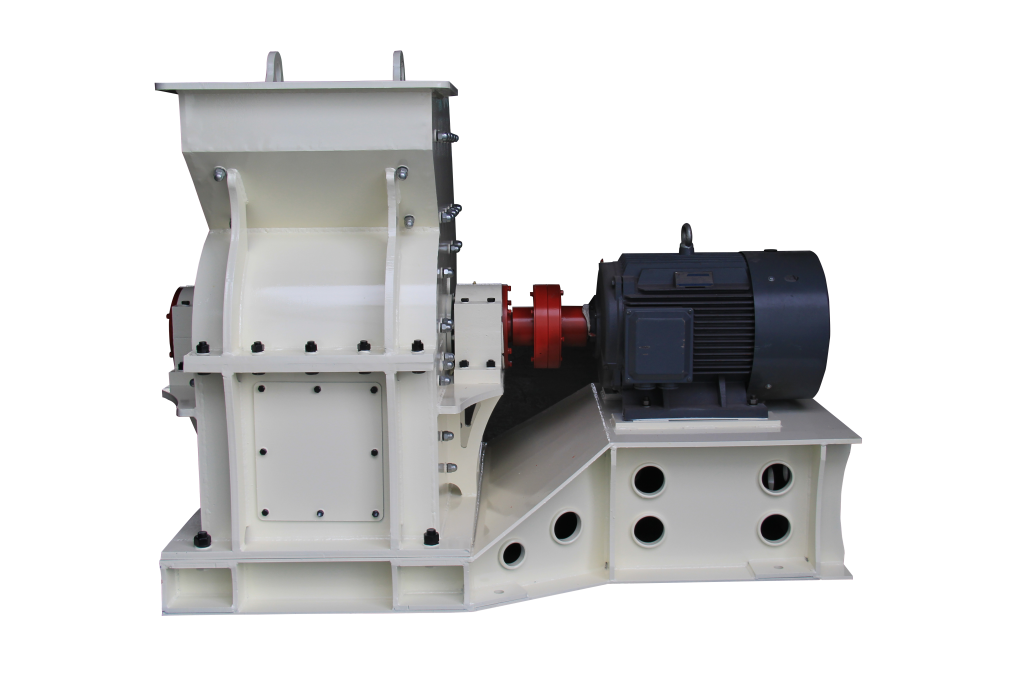

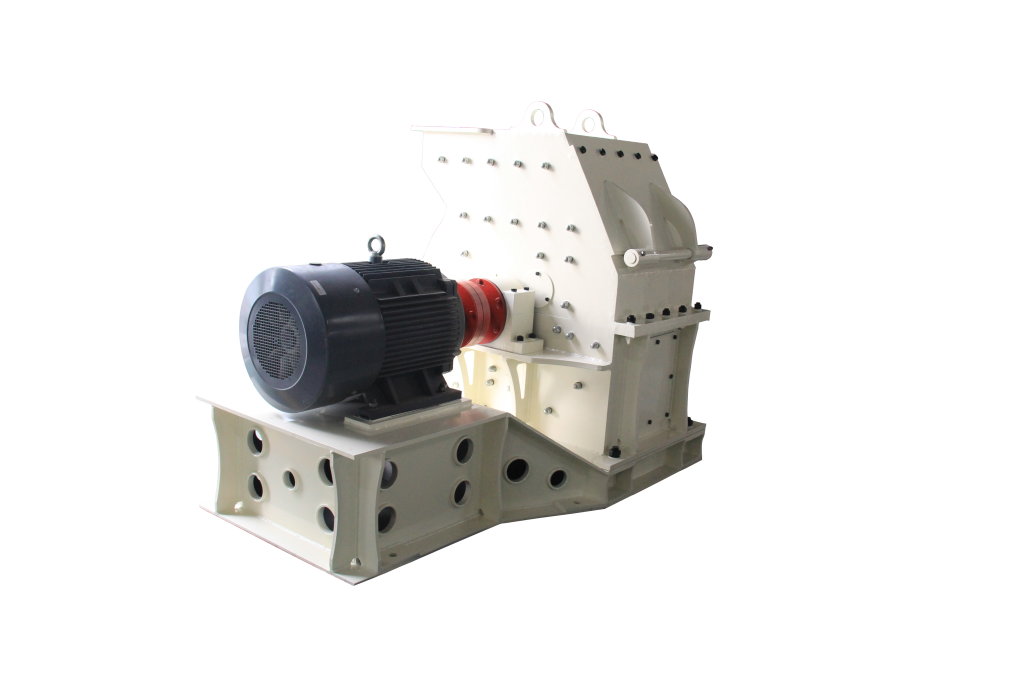

Feldspar European Hammer Crusher

Brief Introduction

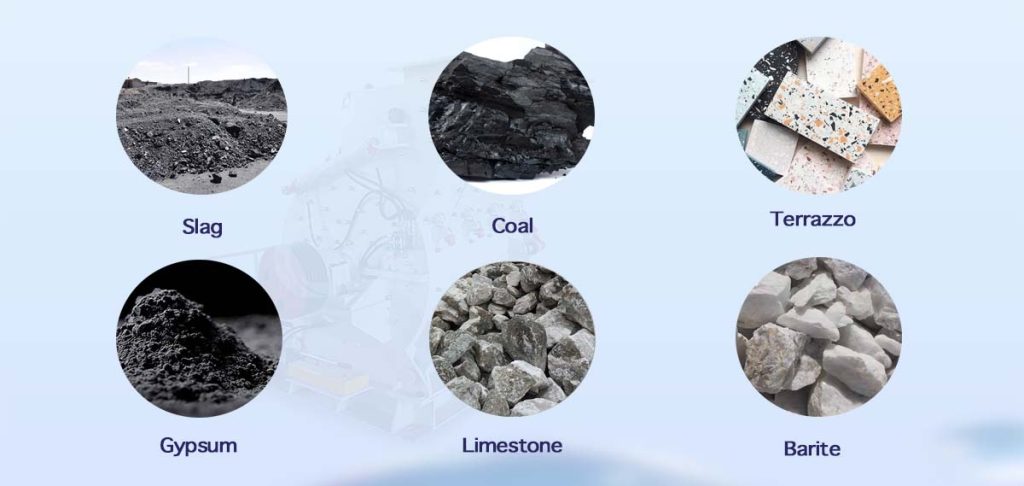

Feldspar Hammer Crusher is equipment using high-speed rotary hammers to crush materials, mainly applied to the industries of metallurgy, mining, chemistry, cement, construction, refractory materials and ceramics. It can crush hard and soft ores into medium or small size, such as barite, limestone, gypsum, terrazzo, coal, slag, and up to 100 different kinds.

Work Principle

Primary Crushing

After being crushed by a hammer crusher, the large materials are reduced to smaller pieces. These smaller pieces are then transported to the storage hopper using an elevator. From there, they are evenly distributed to the upper distribution plate of the turn plate by a vibrating feeder and a sloping feeding pipe.

Mill Operation

When the grinding mill operates, the main bearing and each dial are powered by an electromotor via a reducer. The grinding rollers roll within the ring channels, driven by the plunger through the dial.

Material Centrifugation

The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers.

Airflow Classification

The high-pressure air blower constantly inhales air, carrying crushed materials to the classifier. The impeller there separates the particles: oversized ones fall back to the mill for re-grinding, while the right-sized ones enter the cyclone powder collector.

Powder Collection and Packaging

Most qualified powders descend and exit through the bottom discharge valve. A small portion of fine powders, carried by air, proceeds to the dust cleaner. Both streams are then conveyed to be packaged into finished powders.

Air Emission

In addition, filtered clean air will be emitted from the muffler in the end.

Advantage

High capacity, high crushing ratio.

Uniform particle size, simple structure.

Low investment, easy management and maintenance.

Specification

| Model | PC400x300 | PC600x400 | PC800x600 | PC1000x800 |

| Rotor Diameter (mm) | 400 | 600 | 800 | 1000 |

| Rotor Width (mm) | 300 | 400 | 600 | 800 |

| r/min | 1100 | 1000 | 960 | 980 |

| Input Size (mm) | <100 | <220 | <350 | <400 |

| Output Size (mm) | 0-10 | 0-20 | 0-25 | 0-25 |

| Capacity (t/h) | 3-8 | 8-15 | 15-45 | 40-60 |

| Power (kw) | 11 | 18.5 | 45 | 75 |

| Hammer Number (pcs) | 16 | 20 | 28 | 30 |

| Weight (ton) | 0.5 | 1.6 | 4 | 6.5 |

| Dimension (mm) | 855*795*860 | 1150*1095*1230 | 2360*1490*1415 | 3072*1720*2121 |