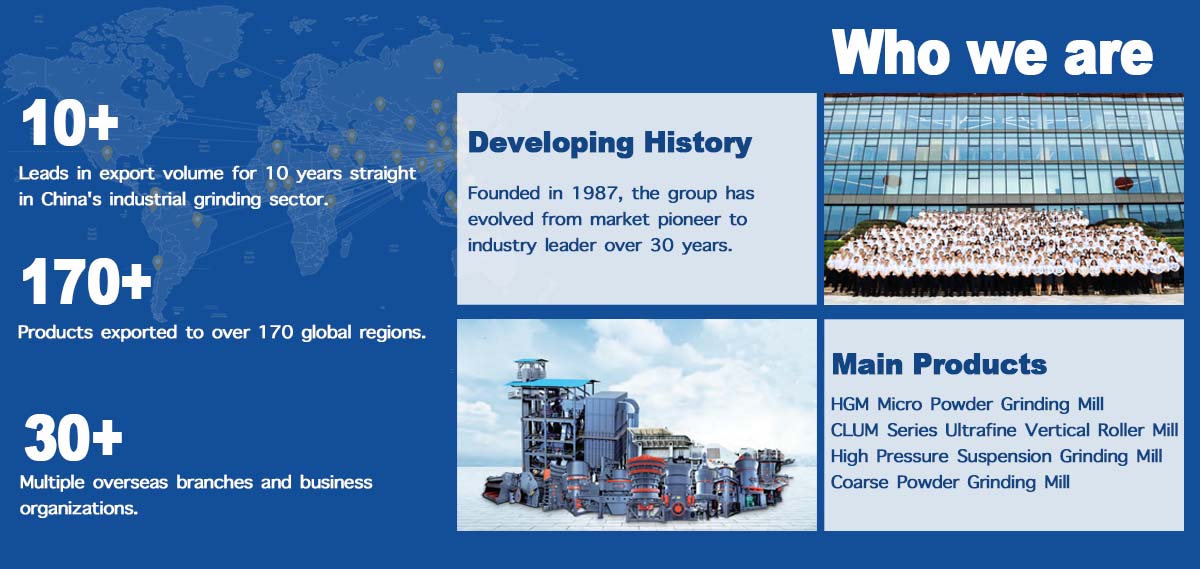

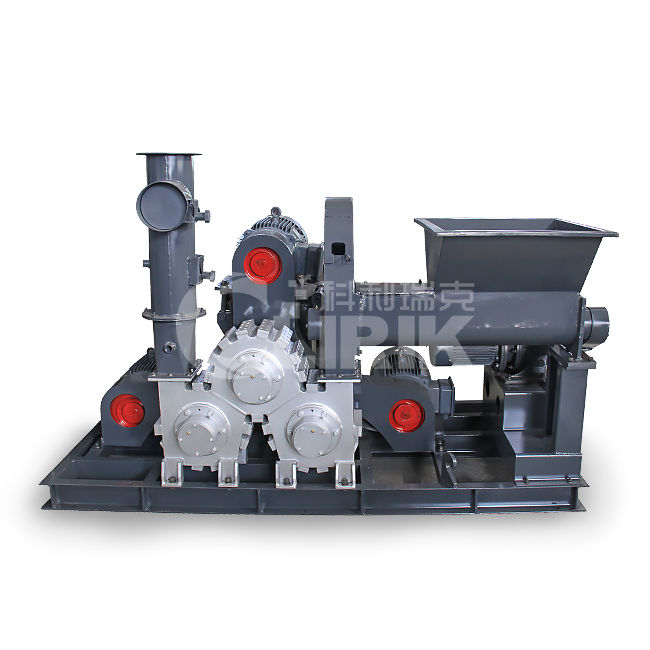

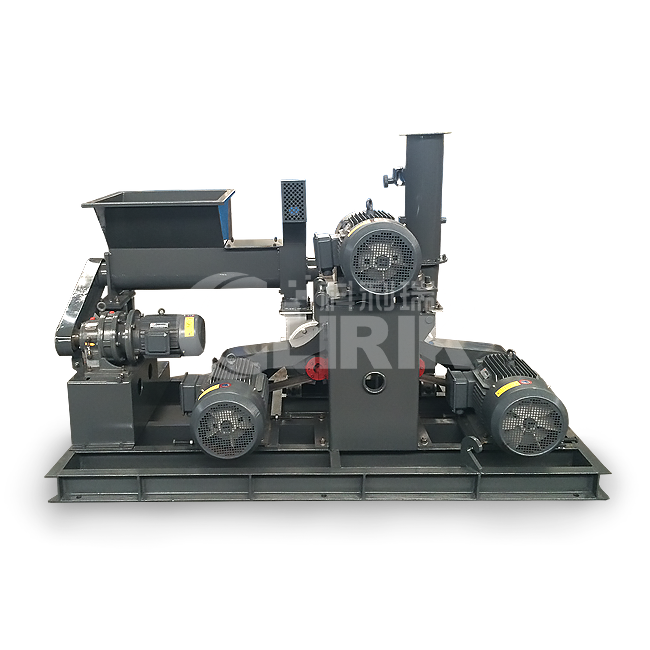

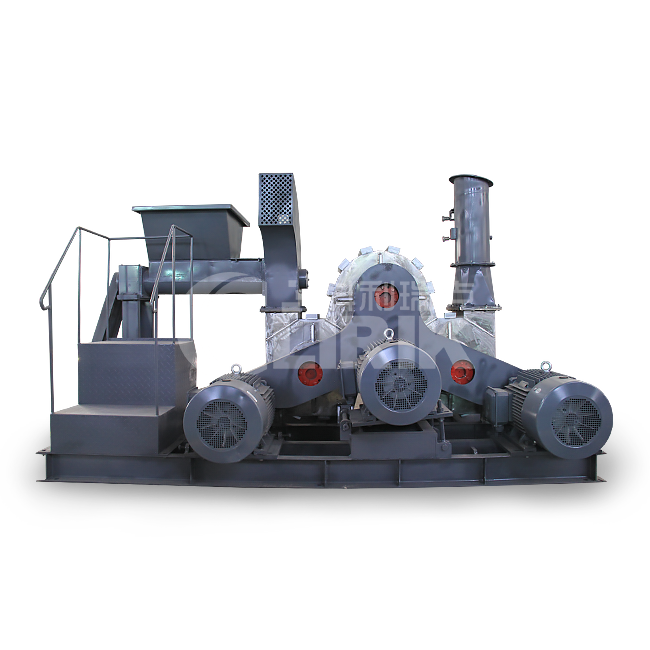

Feldspar Powder Surface Coating Machine

Brief Introduction

The Feldspar Powder Surface Coating Machine is widely used in industries like fillers, pigments, plastics, rubber, and polymer materials. It improves the mix of inorganic fillers with organic polymers, strengthens materials, and saves costs by increasing filler usage. Clirik's CLG machine is designed for continuous powder modification, ensuring efficient and high-quality results.

Application

This machine's unique cavity design offers both modification and depolymerization, suitable for a variety of materials.It achieves great surface modifications for materials like calcium carbonate, kaolin, talc, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesium hydroxide, barium sulfate, claystone, and pyrophyllite.

Structure and Characteristics

Hopper

The material enters the hopper of Feldspar Powder Surface Coating Machine from the bin or bag, and the feed water content should be less than 0.5%.

Conveying device

Adopt double screw conveying material, frequency conversion control feed speed to ensure stability.

Agent adding system with temperature control

The melting temperature of the agent can be set arbitrarily, which is suitable for all kinds of modified agents in solid and liquid form.

Main machine

Consisting of 3 modifying rollers in triangle form, compact design, high efficiency and stable running.

Cyclone dust collector

diffusion type.

Impluse type bag dust collector

new generation pleat filter, with the advantage of little space, large filtration area, high removal efficiency and easy cleaning.

Working Principle

The powder surface treatment is completed mainly by means of three modifying rollers. The dry powder and dosed agent are put into modifying rollers simultaneously. With high speed rotation, the materials and agent is running in the form of fluidizing vortex. The modification is completed with the heat generated by high speed shearing, colliding and friction among the rotor, stator and the powder.

Working Features

Continuous production, large capacity.

The modified agent has high utilization rate, small dosage and low energy consumption.

Both modifying and dispersion function, suitable for any fine materials, special active effect for material with small proportion and big cubage weight like white carbon, mica powder and talcum powder.

Powder and agent mixing and running in high speed and vortex, high modifying efficiency, with little change of granulate shape.

Running at vacuum, air tight, no dust leakage, no pollution, good operation condition, low labor intensity.

Operating in heat and cold conditions, no additional heating or cooling system required, easy operation.