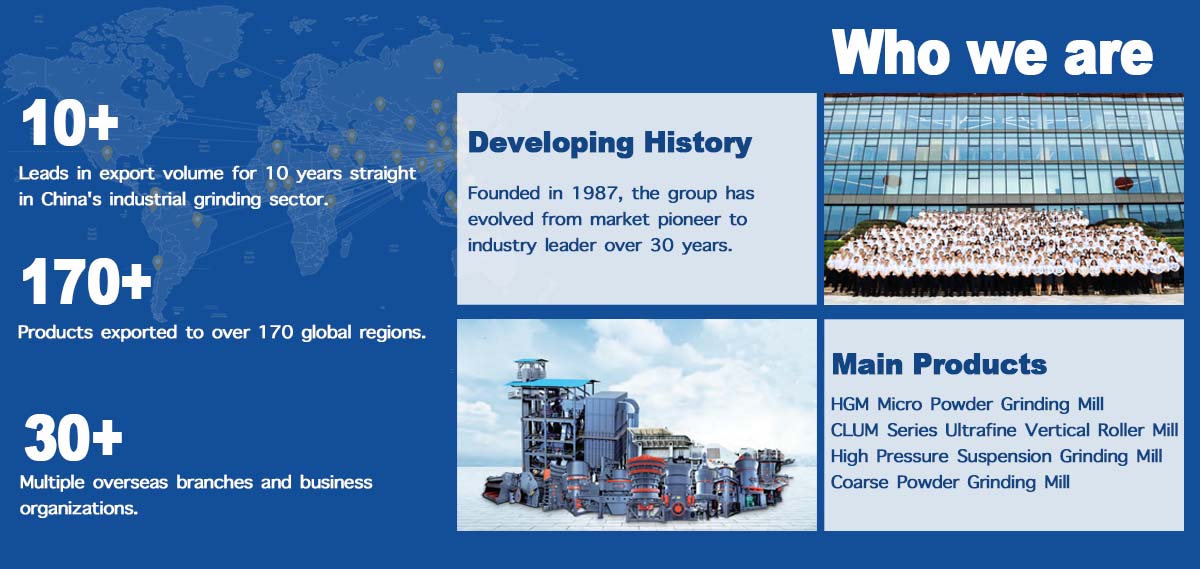

HGM Series Feldspar Micro Powder Grinding Mill

Brief Introduction

The HGM Series Feldspar Micro Powder Grinding Mill offers efficient, low-energy ultrafine grinding. It adjusts material fineness from 325 to 2500 mesh, achieving D97≤5μm. It's a cost-effective alternative to jet and ball mills.

Application

HGM Series Feldspar Micro Powder Grinding Mill is used in industries like metallurgy, mining, and construction. It grinds materials under 9 Mohs hardness and 6% humidity, like kaolin, limestone, calcite, talc, marble and marble.

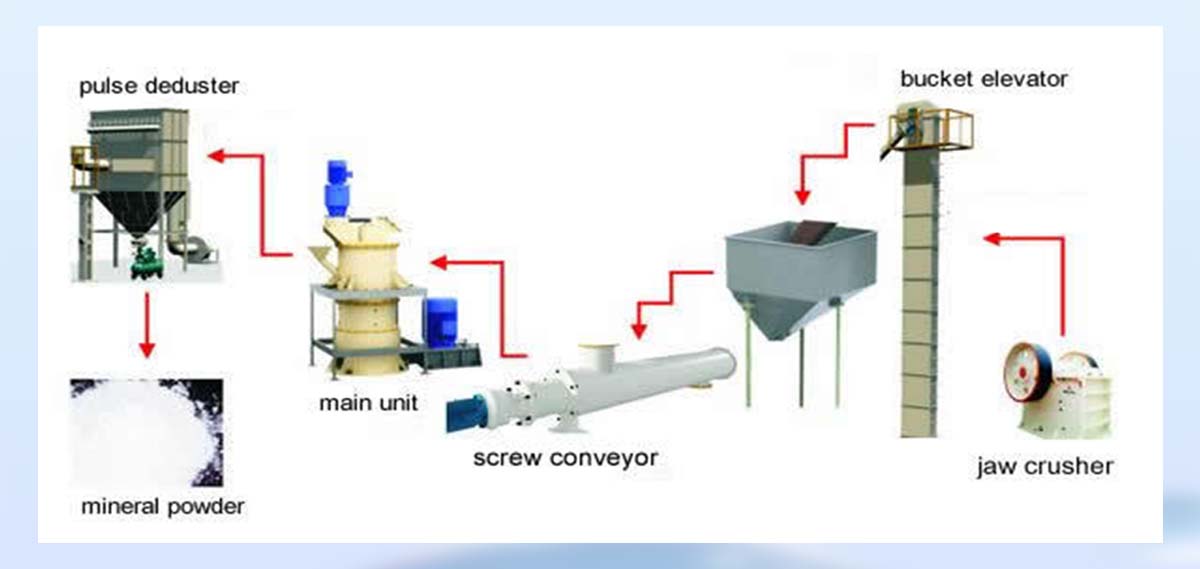

Production line of Feldspar Powder Making Machine

Rolling and Centrifugal Force

The grinding rollers rotate within the ring, and the centrifugal force drives the materials to the edge of the turn plate.

Grinding and Crushing

The materials fall into the grinding chambers where they are repeatedly pressed, crushed, and ground by the rollers.

Airflow and Classification

The high-pressure air blower inhales air, and the airflow with crushed materials is directed to the classifier.

Separation and Recycling

The classifier's impeller screens the airflow; over-sized particles fall back into the mill for re-grinding, while qualified particles mix with air.

Collection and Cleaning

Qualified particles enter the cyclone powder collector, where most of the powder falls out through the discharge valve, and fine powders move to the dust cleaner.

Packaging and Emission

The collected powders are sent to the bottom conveyor for packaging, and the clean air is emitted from the muffler's air outlet.

Specification

| Model | HGM80 | HGM90L | HGM100L-Ⅱ HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number (layer) | 3 | 3-4 | 4 | 4 | 4 |

| Roller Number(piece) | 18-21 | 24-29 | 28-36 | 30-40 | 30-44 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size (mm) | ≦20 | ≦20 | ≦20 | ≦20 | ≦20 |

| Finished Size (μm/mesh) | 74-5 (200-2500) | 74-5 (200-2500 | 74-5 (200-2500) | 100-6 (150-2000) | 100-9 (150-1500) |

| Capacity (t/h) | 0.5-5.5 | 0.8-6.5 | 1.2-10 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (m) | 15.1*4.2*7.3 | 18.4*3.9*7.8 | 22.7*3.6*8.5 | 27.3*4.2*9.9 | 31.7*7.7*12.6 |