Feldspar has a Mohs hardness of 6 and a low melting point, making it widely used in the production of ceramics, glass, and potash fertilizers. Feldspar powder is produced by feldspar grinding mill, which has brittleness, high compressive strength and stable chemical properties.

Due to the increasing demand of feldspar powder in recent years, processing feldspar into 80-300 mesh powder will produce more objective economic benefits.

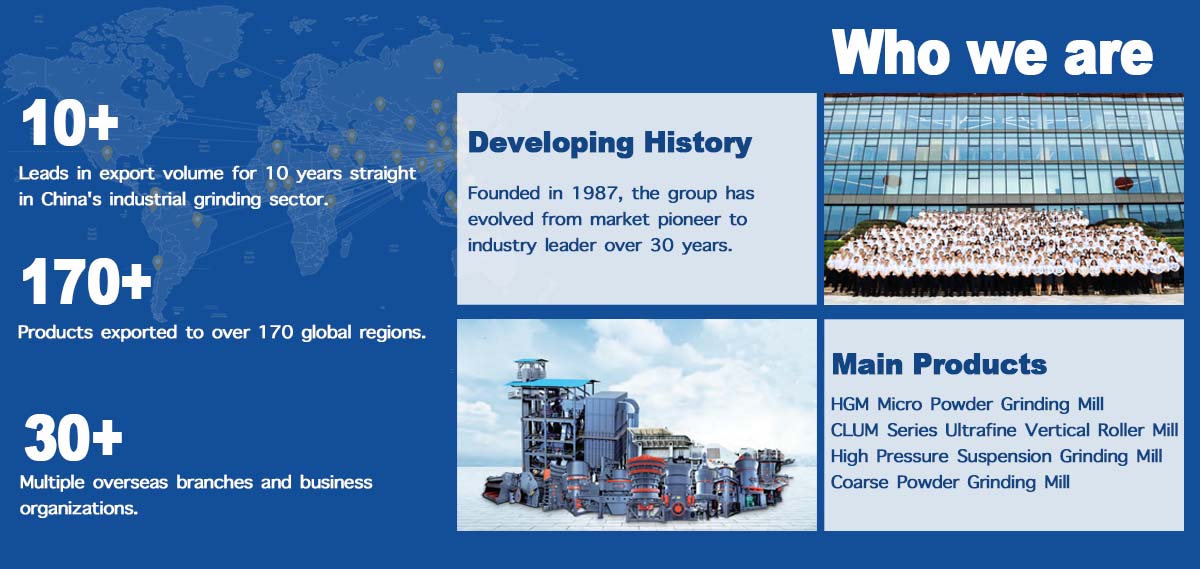

Below is a detailed introduction to the process flow and equipment configuration for feldspar crushing and grinding.

Feldspar grinding production process and other mineral grinding process is roughly the same, by crushing, screening, feeding and conveying composition.

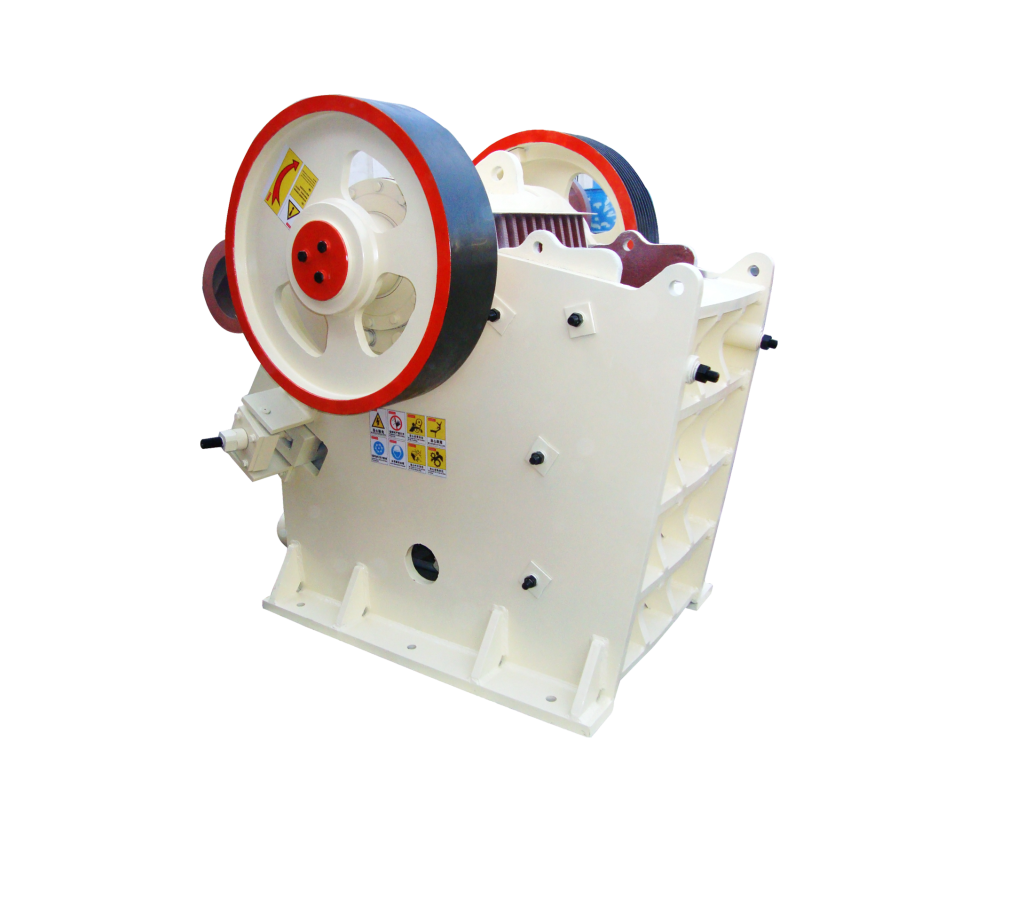

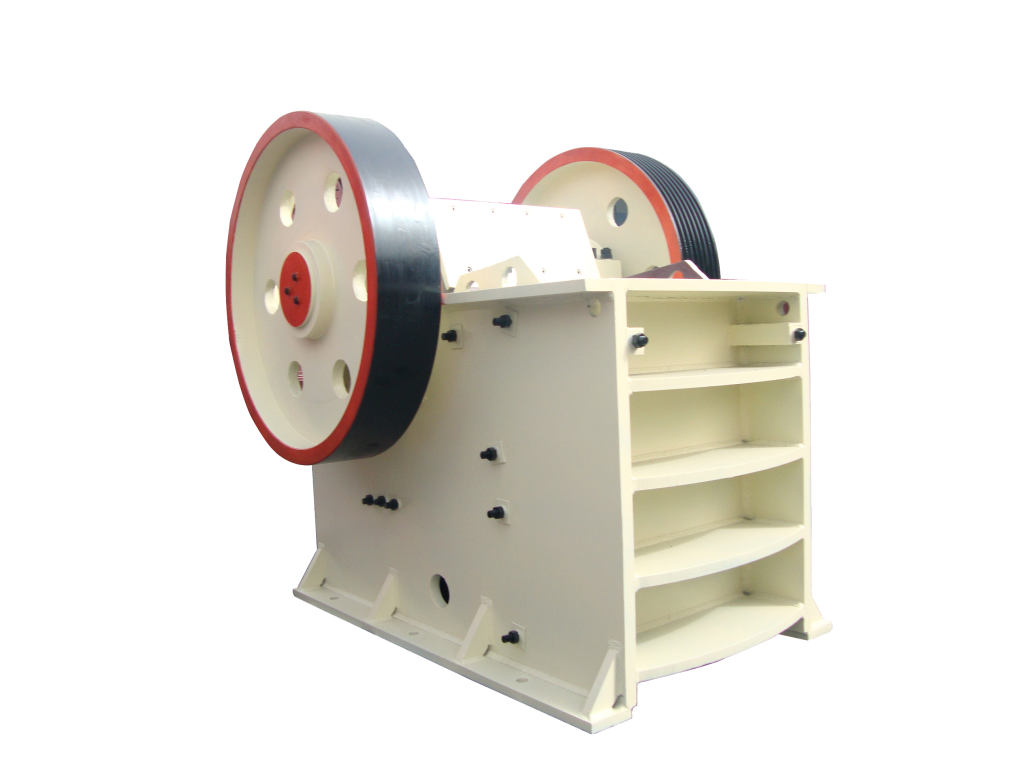

Jaw Crusher

Before grinding, the large feldspar needs to be broken into smaller pieces. Crushing equipment is usually used clirik jaw crusher. It has the advantages of high yield, large crushing ratio, large feed particle size, and is not easy to damage. The crushing process is completed through a combination of coarse crushing and fine crushing operations.

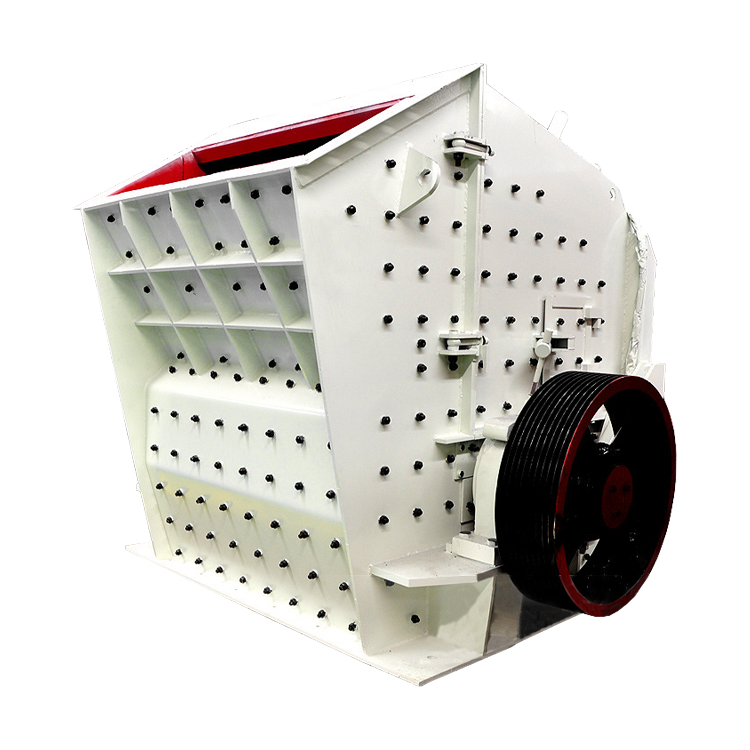

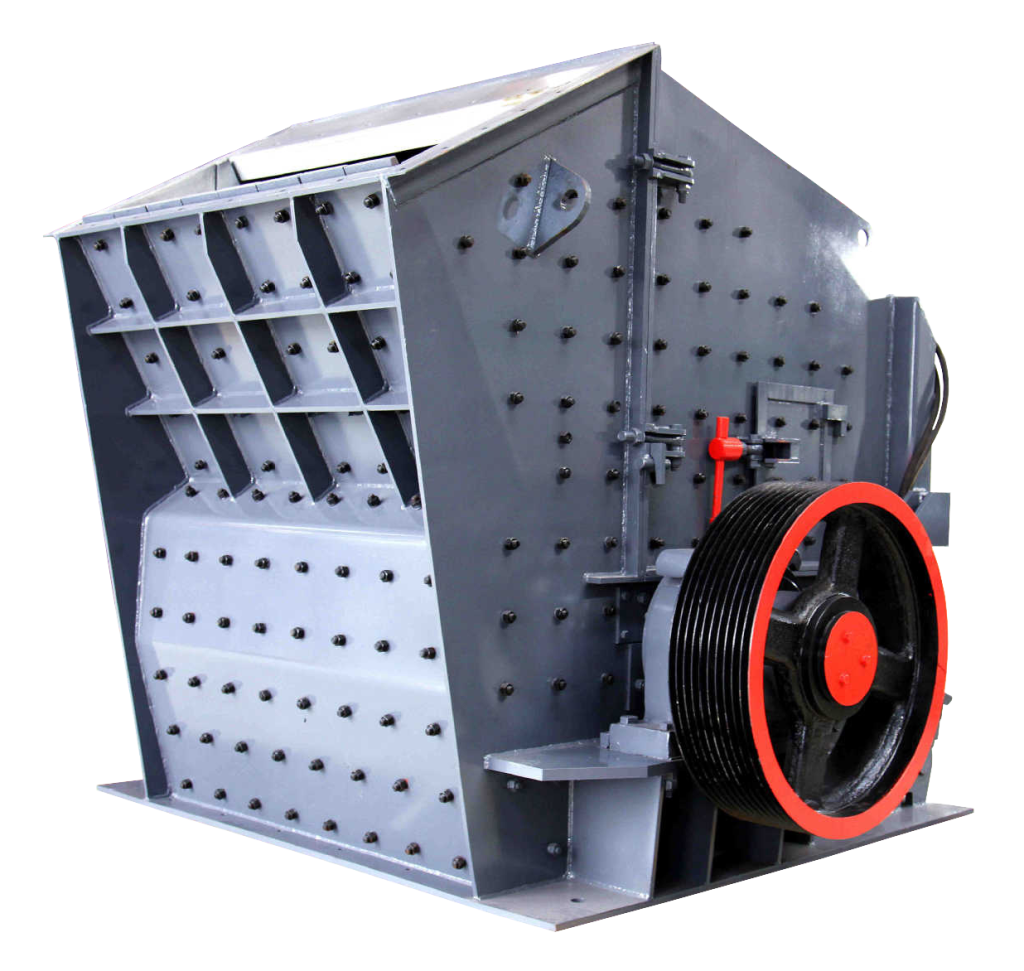

Impact Crusher

Clirik Impact crusher can handle the side length of 100-500 mm below, crushing hardness of low materials, crushed particles are cube, high pressure resistance up to 350MPA, widely used in railway, road, building materials, ore crushing, energy, transportation, cement, chemical mining and other industries of the medium and fine crushing operation.

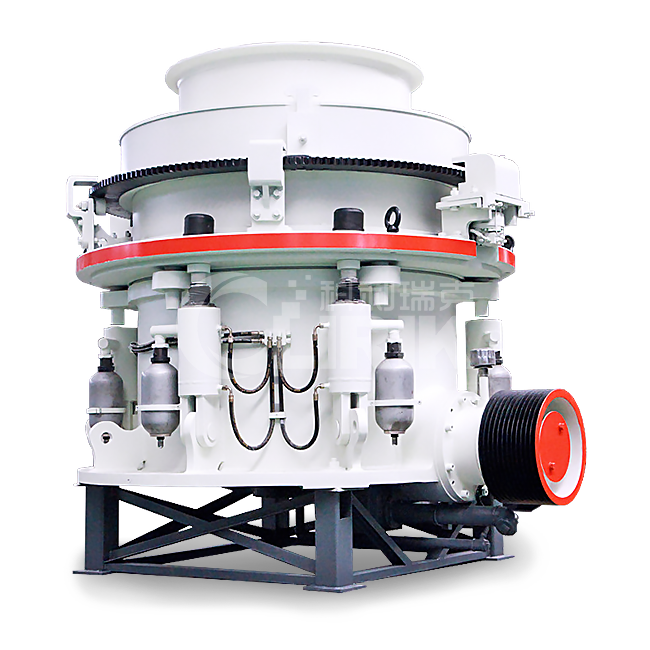

Cone Crusher

Cone crusher is a kind of crushing machinery suitable for metallurgy, road construction, chemical industry, silicate and other raw materials, according to the crushing principle and product particle size is different, divided into a variety of models. Cone crusher has the advantages of reliable structure, high productivity, good particle size and shape of finished products, convenient adjustment, and reducing operating costs.

There are four types of Clirik cone crusher: compound cone crusher, spring cone crusher, hydraulic cone crusher and rotary crusher. Cone crusher is suitable for crushing hard materials, such as calcite, limestone, granite, dolomite, bluestone, glass, basalt, iron ore and so on. It is very popular in large stone factories.

Vibrating screen

Vibrating screen is a screening equipment. It is widely used in metallurgy, mining, coal, building materials, electric power, chemical industry and other industries. The Clirik vibrating screen has the advantages of long service life, low noise and high screening efficiency. There are many types and models of vibrating screens. The corresponding production capacity and displacement of different models of equipment are also different. This can meet the needs of different customers. It uses strong vibration to sift the raw material through the sieve. By replacing the sieve of various specifications, the finished product of different discharge particle size is obtained.

Auxiliary equipment

The auxiliary equipment for this production line includes the vibrating feeder, belt conveyors, dust removers, wear parts, etc.

Please contact Clirk for more information or to upgrade your device.