Lithium source demand surges with electric cars and renewable energy. Traditional methods of lithium extraction mainly rely on lithium ores, such as mining spodumene, lepidolite, and lithium salt lakes. However, as resources become increasingly scarce, some companies have begun to seek new avenues for lithium extraction. Among them, lithium source extraction from feldspar, as an emerging technology, is gradually gaining attention.

Feldspar, a common mineral, holds promise for lithium extraction. Chemical processes can efficiently extract lithium from it. This method boosts resource availability and reduces environmental harm. Compared to traditional lithium ore mining methods, lithium extraction from feldspar demonstrates higher environmental friendliness and cost-effectiveness.

As the demand for lithium source continues to grow, the development of lithium extraction technology from feldspar is crucial for ensuring a sustainable lithium supply chain. The advancement of this technology not only broadens the sources of lithium resources and reduces dependence on traditional mining methods but also provides a more stable and environmentally friendly supply of lithium for various industries. By utilizing alternative resources such as feldspar deposits, we can meet the growing demand for lithium while promoting the sustainable use of resources.

How to Extract Lithium from Feldspar?

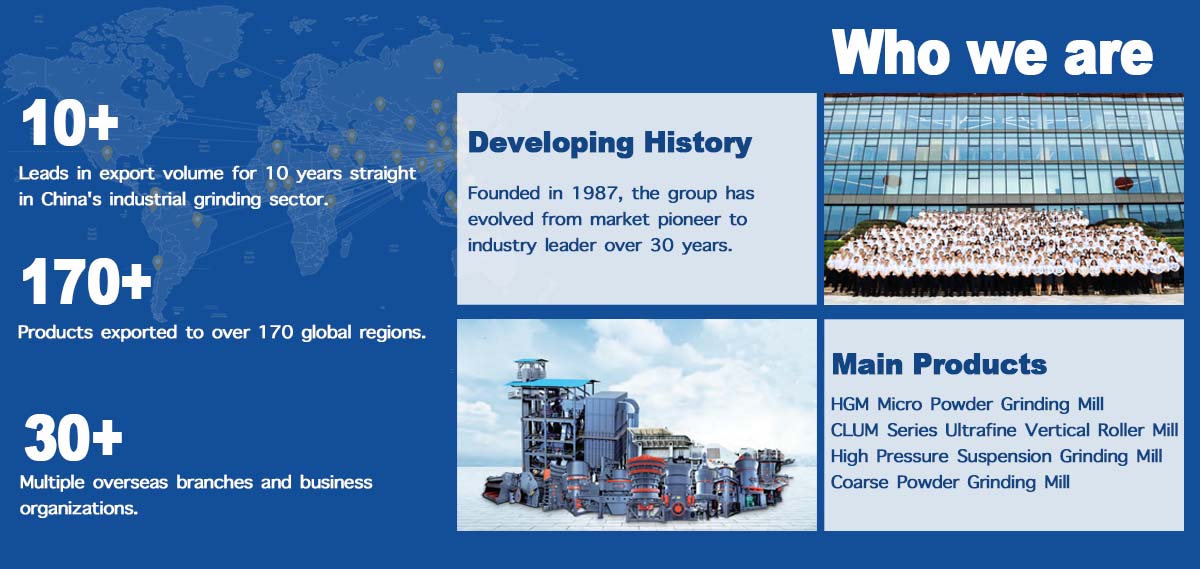

In the field of lithium extraction, the Clirik HGM Micro Powder Grinding Mill plays a key role. This equipment can grind feldspar into extremely fine powder, significantly improving the efficiency of lithium extraction during the chemical treatment process. With its high efficiency and energy-saving characteristics, the Clirik HGM Ultrafine Grinding Mill has become an indispensable piece of equipment in the process of lithium extraction from feldspar.

It is not only suitable for lithium extraction projects but also widely used in various industries such as building materials, chemicals, fillers, plastics, paper, and paint production. It handles brittle materials under Mohs 9 hardness, like mica and limestone.

Feldspar extraction eases reliance on traditional lithium ores. It opens paths for sustainable lithium development. As technology advances, this method will be crucial for lithium resource development. It contributes to global energy transition and sustainability.

Clirik HGM mill's performance will aid this progress. It pushes the lithium extraction industry towards higher efficiency and environmental protection.