Potassium feldspar is widely used in ceramics, glass, electrical porcelain, abrasive materials and potash fertilizer industries. As demand grows, the industrial value of potassium feldspar is getting higher and higher. Therefore, it is very important to remove impurities, especially iron, during processing.

Application of potassium feldspar

Potassium feldspar is extensively used in the production of ceramic bodies, glazes, fire-resistant calcium silicate boards, glass and enamel industries, abrasive materials, etc. Its aesthetically pleasing colors make it a popular choice for decorative stones and semi-precious gems. Additionally, high-quality potash feldspar is utilized in the manufacturing of TV display glasses and can also be used to produce potash fertilizers.

The Process of Deironing and Beneficiation of Potassium Feldspar

Process of impurity removal

Photoelectric sorting

Use photoelectric sorting machine to separate raw ore, remove waste rock and impurities, and improve sorting efficiency.

Magnetic separation

Remove weak magnetic impurities in feldspar, such as iron minerals, biotite, etc.

Flotation process

Remove ferrite-containing minerals, such as pyrite, mica, etc.

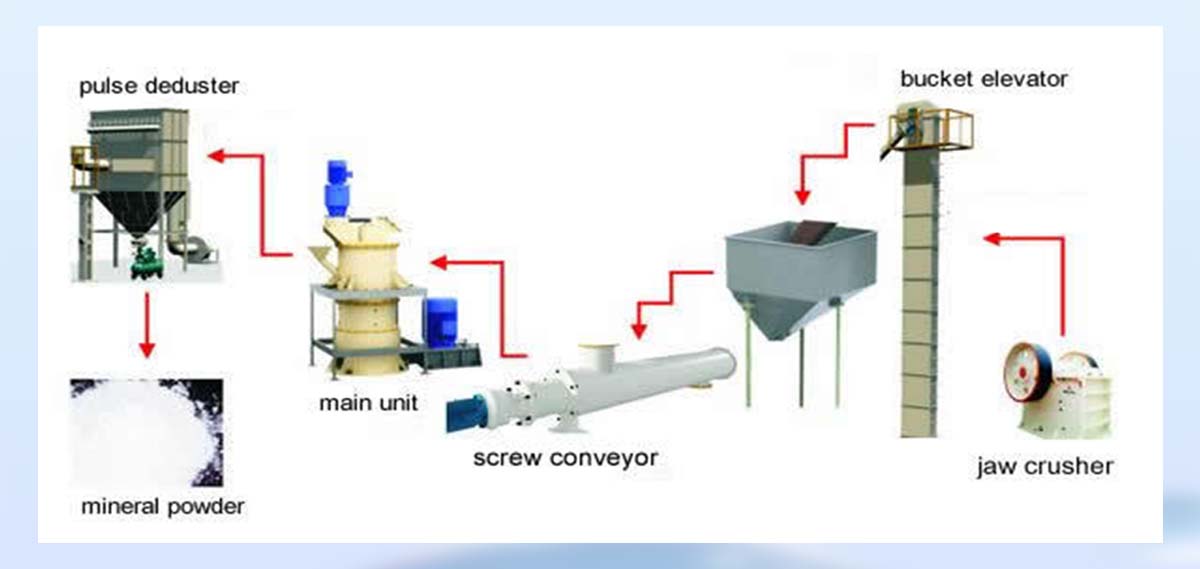

The Process flow of Beneficiation equipment

Crushing

The raw ore is first crushed by a jaw crusher. It then moves to a cone crusher on a belt conveyor for more crushing.

Sorting

After secondary crushing, potassium feldspar particles are screened. They are sent to a sorting machine for further classification. Waste rock is thrown away.

Grinding

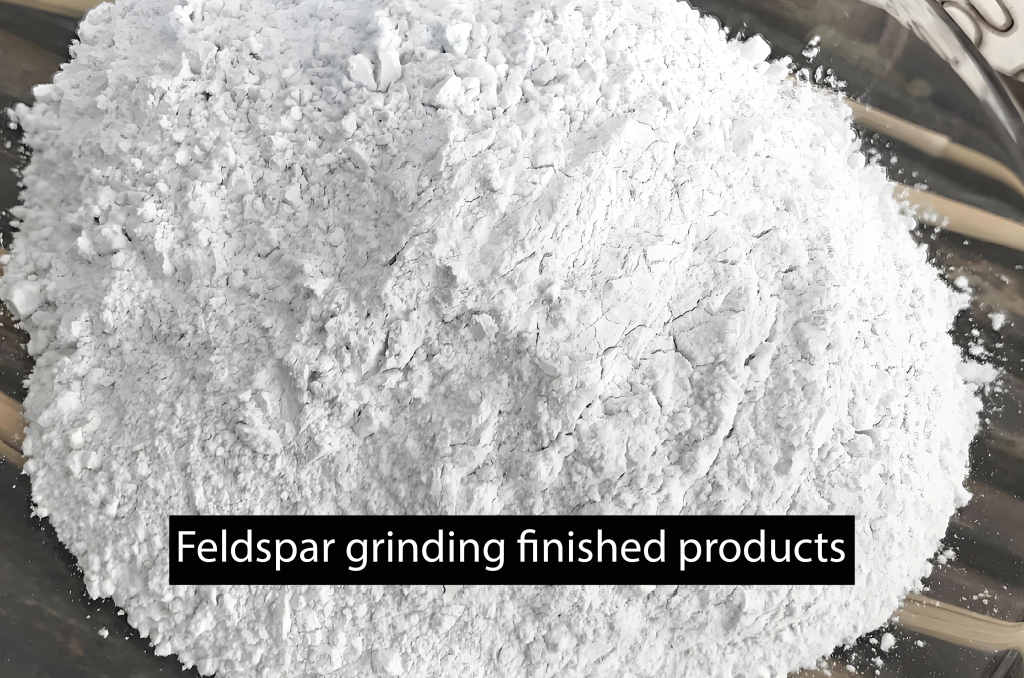

The concentrate waste is ground. The resulting potassium feldspar powder is sorted in a spiral classifier.

Magnetic separation

The fine-ground potassium feldspar powder goes through magnetic separation. Strong magnets remove iron and mica.

Flotation

Feldspar flotation removes iron and titanium. It also separates quartz and other materials. Different methods are used depending on the feldspar's condition.

Dewatering and drying

After separation, the feldspar is dewatered in a concentrator. It then goes to a dryer for quick drying. The dried powder is the final product.

Introduction to Feldapsr Processing Equipment

The equipment required for the potassium feldspar mineral processing process includes a jaw crusher, cone crusher, grinding machine, vibrating feeder, spiral classifier, ore color separator, artificial intelligence separator, magnetic separator, flotation machine, dryer, vibrating screen and conveyor. Depending on the different forms of potassium feldspar present variations in the necessary equipment may occur.

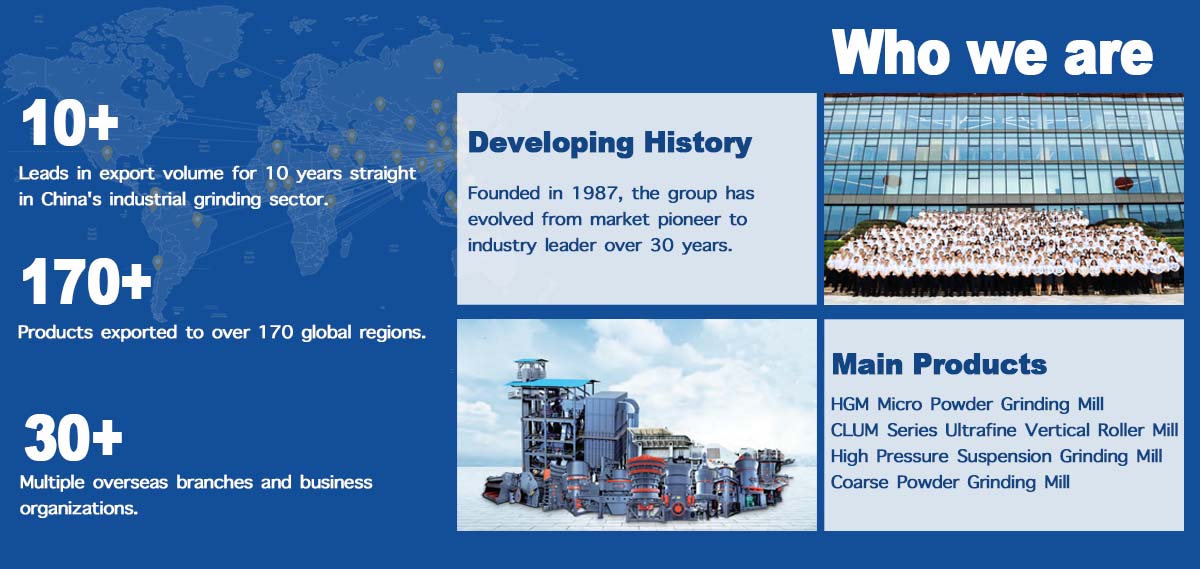

Shanghai Clirik, a renowned company in the mining industry, is dedicated to manufacturing top-notch mining equipment. With a strong emphasis on quality and innovation, they have gained global recognition for their exceptional products. One of their flagship offerings includes the production of ore mills, which are widely acclaimed for their efficiency and reliability.

The ore mills manufactured by Shanghai Clirik have revolutionized the mining sector with cutting-edge technology and advanced features. These mills are designed to efficiently handle various types of ores, ensuring optimal extraction and processing. Their popularity can be attributed to their ability to deliver high-quality output while minimizing energy consumption.