Feldspar powder, as one of the key ingredients in glass batch, helps to lower the melting temperature of quartz and maintain the viscosity of glass within the desired range by acting as a flux. The alkali metal content in feldspar, primarily potassium and sodium, is key to its effectiveness as a flux in glass production. This characteristic allows for a reduction in the overall energy demand required for specific melting, making the process more energy-efficient. Feldspar powder abrasive grinding mill can also provide aluminum to the glass, thereby enhancing its strength and transparency.

Feldspar powder used in the glass industry is typically ground to a specific fineness to ensure it can effectively bind with other materials in the glass batch.

The feldspar powder abrasive grinding process includes:

01 Crushing the raw materials to a size that can enter the mill (15mm-50mm).

02 Grinding in the Feldspar powder abrasive grinding mill.

03 Separating out coarser particles through classification, which are returned to the mill for further grinding.

04 Collecting the finished product that has reached the required fineness.

We supply potassium feldspar grinding mills. The potassium feldspar grinding mill includes a feed hopper, belt feeder, ball mill, air classifier, and bag filter.

In combination with other raw materials, feldspar powder is mixed with other ingredients such as silica sand and alumina in the glass batch. This mixing process is crucial for forming a uniform mixture that will eventually transform into glass during the melting process. The addition of feldspar powder not only facilitates the melting process but also enhances the final properties of the glass, such as increased hardness, durability, and chemical resistance. The alumina and calcium ions in feldspar are particularly responsible for these effects.

Using feldspar as a flux in glass manufacturing does not change the redox number of the batch, which is beneficial as it avoids the need for additional materials to counteract any changes. This makes feldspar a more environmentally friendly addition to the glass batch, as it requires less energy and does not necessitate the use of other materials.

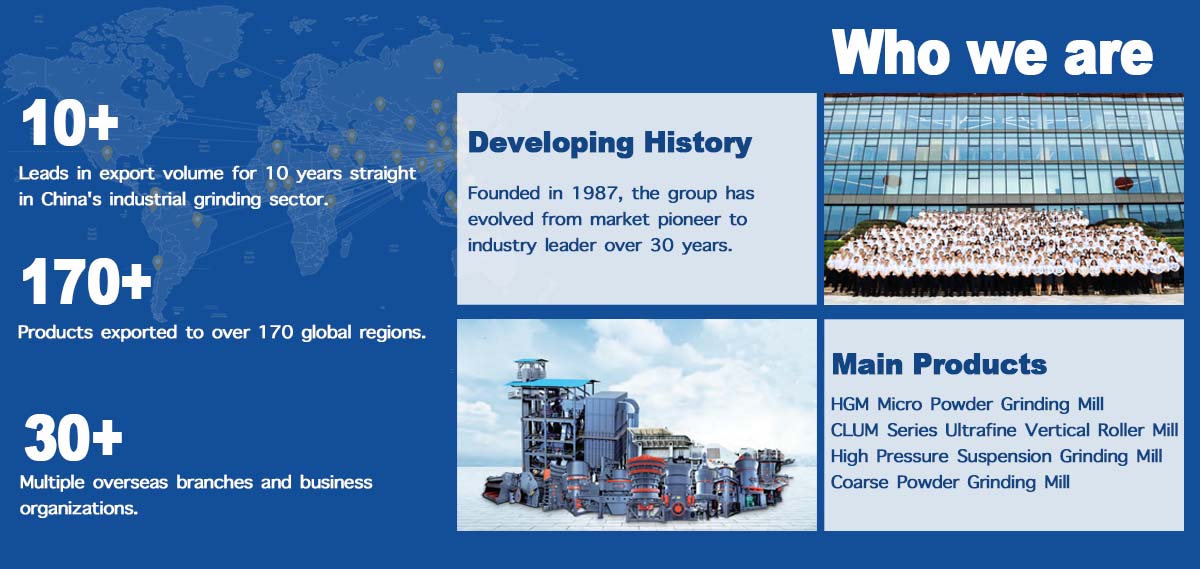

SHANGHAI CLIRIK MACHINERY CO., LTD is a Chinese company specializing in the production of large and medium-sized crushing, sand-making, and grinding equipment. We are committed to providing customers with cost-effective products and comprehensive technical support. We welcome customers interested in feldspar grinding mills to inquire and learn more about our equipment and solutions to improve your production efficiency and product quality. We look forward to working with you to explore more possibilities of feldspar powder grinding abrasives in industry.