While quartz is renowned for its composition of oxygen and silicon atoms, feldspar stands out with its additional aluminum content. Silicon is the cornerstone of quartz, contrasting with the aluminum that defines feldspar. The structural units of these minerals diverge, with quartz forming SiO4 units and feldspar comprising a complex KAlSi3O8 - NaAlSi3O8 - CaAl2Si2O8 structure.

The Difference Between Feldspar And Quartz

Hardness is a distinguishing factor, with quartz being the harder of the two. Despite this, feldspar's softer nature does not detract from its versatility. The color palette of feldspar is more diverse, ranging from purple to brown, compared to the lighter hues of quartz. Crystalline structures also differ, with quartz exhibiting a hexagonal pattern and feldspar presenting triclinic or monoclinic forms.

Quartz's piezoelectric properties have earned it a place in the gemstone and electronics industries, while feldspar's applications are vast within ceramics and glass. For the grinding of albite, a common feldspar mineral, mills such as the Feldspar mill, Raymond mill, or ultra-fine ring roller mill are recommended. Albite's glassy crystals, with a Mohs hardness of 6-6.5, are integral to the production of ceramics, soap, tiles, and glass, with a significant presence in ceramic glazes.

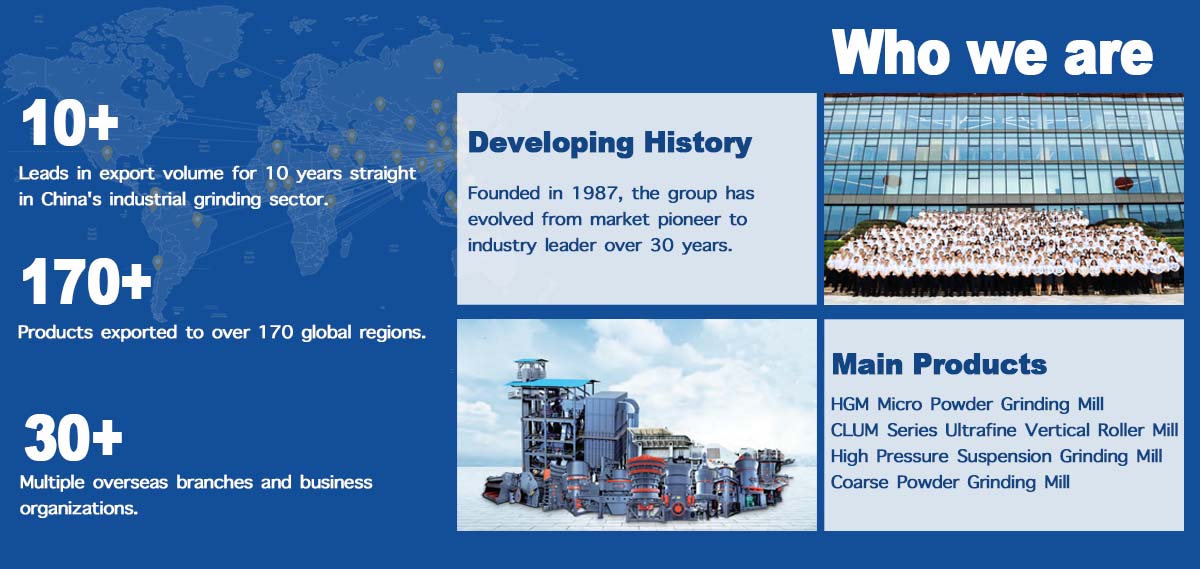

The Ultra-fine Vertical Roller Mill, with its advanced European technology, is a superior alternative to traditional mills for feldspar grinding. It offers high productivity, consistent fineness, and energy efficiency, with a capacity to grind materials to 3000 mesh fineness.

The HGM Micro Powder Grinding Mill, with a capacity of 0.5-45 t/h and a fineness range of 200-2500 mesh, is designed for high-quality ultra-fine grinding. It is known for its stable performance and ease of operation, making it ideal for fine powder milling.

We have been cooperating with many scientific research institutions at home and abroad for many years, so that our mill R&D capabilities have always been at the forefront of the industry. Clirik, as a leading manufacturer of micro powder grinding equipment, provides you with customized solutions to meet your specific grinding needs. Welcome to consult.