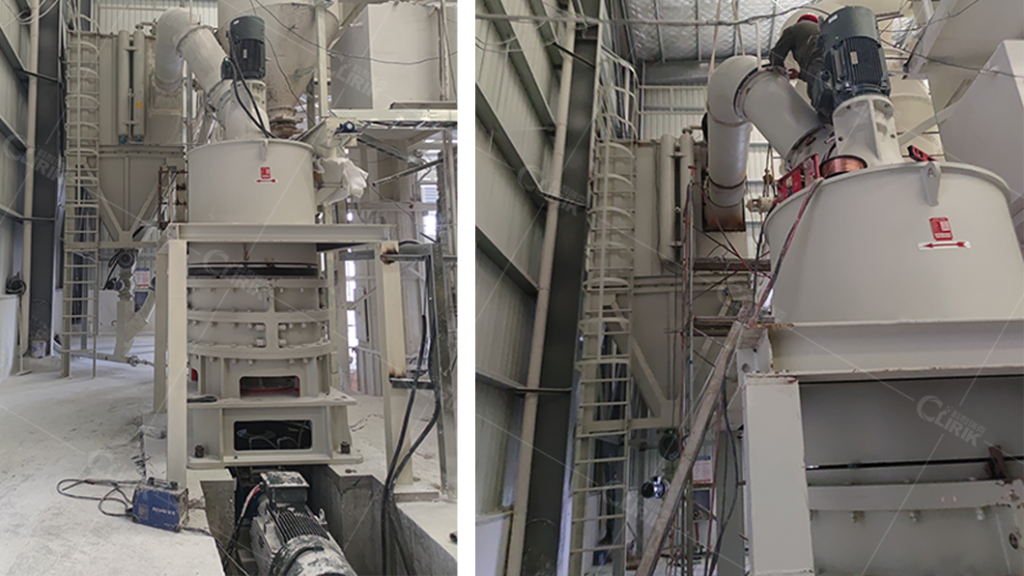

The calcium hydroxide grinding industry in Macedonia has witnessed a significant transformation with the introduction of Clirik's HGM100 ultra fine powder mill. This state-of-the-art equipment has not only enhanced the production efficiency but also improved the quality of the final product, making it a preferred choice for local manufacturers.

The HGM100 mill stands out for its innovative design and advanced technology. It operates on the principle of roller press grinding, where the material is fed into the grinding chamber and subjected to intense pressure and rolling action between the mill rolls and rings. This process ensures thorough and uniform grinding, resulting in a high-quality calcium hydroxide powder with consistent fineness.

One of the most notable features of the HGM100 mill is its energy efficiency. It consumes significantly less power compared to conventional grinding mills, which is a major advantage for Macedonian companies looking to reduce their carbon footprint and operating costs. In fact, the HGM100 mill can achieve the same level of fineness with 30% less energy consumption, making it an environmentally friendly and cost-effective solution.

The durability of the HGM100 mill is another factor contributing to its popularity in Macedonia. The mill rolls and rings, made from special materials, have an extended lifespan, reducing the need for frequent replacements and maintenance. This not only saves time and resources but also ensures the continuity of production, which is essential for meeting the growing demand for calcium hydroxide powder in the region.

Safety is a paramount concern in any industrial operation, and the HGM100 mill does not disappoint. Its design eliminates the risk of bearing and screw failures, which are common issues in traditional grinding mills. This feature ensures that the mill operates smoothly and reliably, minimizing the risk of accidents and downtime.

Moreover, the HGM100 mill offers a high degree of flexibility in terms of product fineness. It can produce calcium hydroxide powder with a wide range of fineness levels, from 325 to 2500 mesh (47-5 microns), and the fineness can be easily adjusted to meet specific customer requirements. This adaptability allows Macedonian manufacturers to cater to diverse market segments and applications.

In addition to its technical advantages, the HGM100 mill also addresses environmental concerns. It is equipped with a pulse jet dust collector and a muffler, which effectively control dust emissions and noise levels. This ensures that the production process is in compliance with environmental regulations and contributes to a cleaner and healthier working environment.

The adoption of Clirik's HGM100 ultra fine powder mill in Macedonia's calcium hydroxide grinding industry marks a significant step forward in terms of technological advancement and sustainability. As the industry continues to grow, the HGM100 mill is expected to remain at the forefront, driving innovation and efficiency.