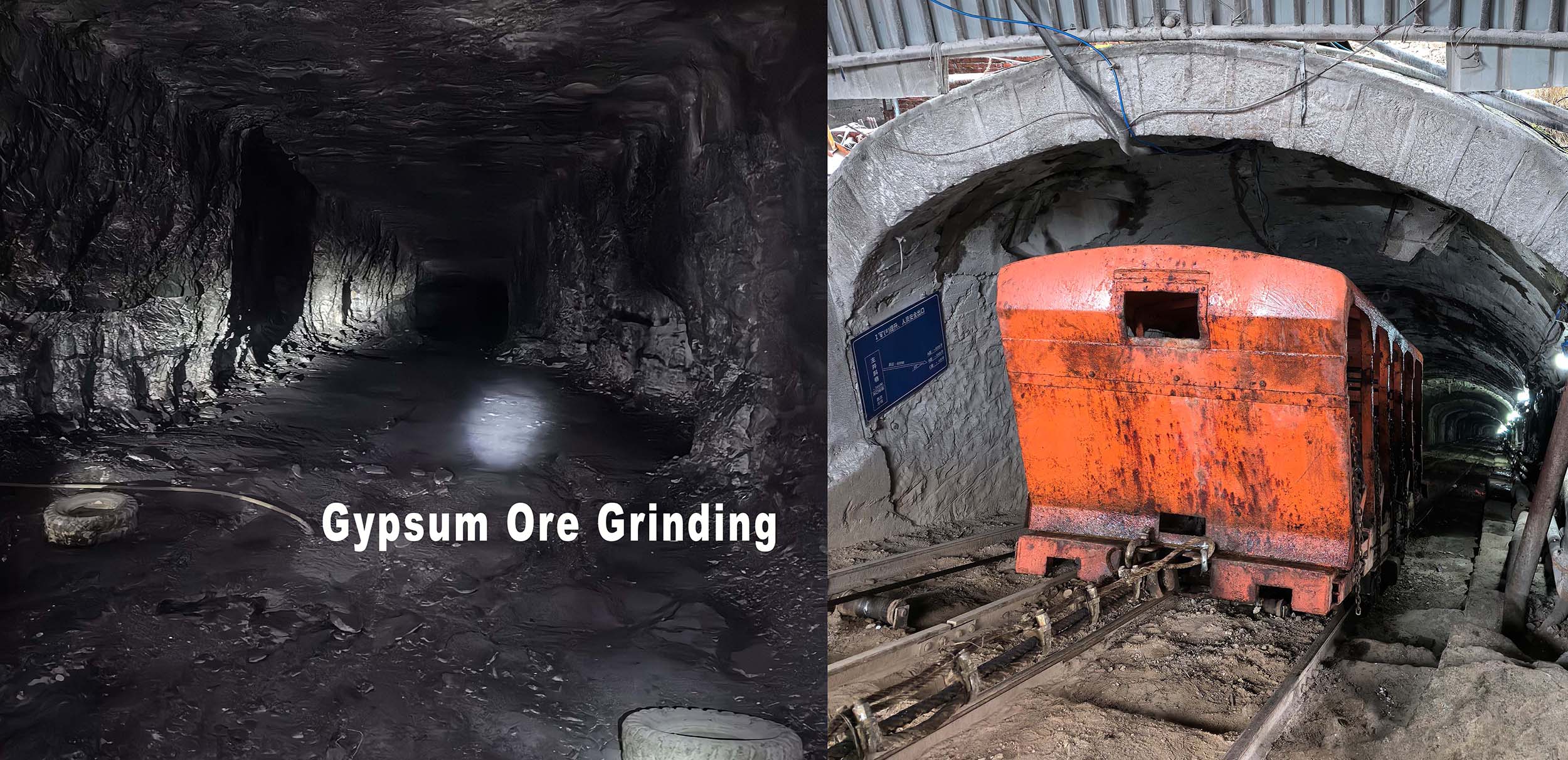

With the increasing global demand for high-quality gypsum products in sectors such as construction, healthcare, and agriculture, Shanghai Clirik Machinery has launched its HGM Grinding Mill, a revolutionary solution that optimizes gypsum ore processing through advanced engineering and sustainable practices.

Gypsum Ore: A Key Mineral for Modern Industries

Gypsum (CaSO₄·2H₂O), a soft sulfate mineral known for its fire resistance and binding properties, is a cornerstone of modern infrastructure development. Its applications are extensive:

- In construction, it represents 70% of global consumption for wallboards and cement retarders.

- In agriculture, it is used as a soil amendment to improve water retention.

- In the medical field, it is utilized for orthopedic casts and dental molds.

- In art, it is employed for sculptures and decorative elements.

Raw gypsum, with a Mohs hardness of 2 and a layered crystalline structure, requires precise grinding to achieve functional particle sizes between 80 and 600 mesh. Traditional grinding mills often struggle with energy waste and inconsistent fineness, challenges that Clirik's HGM series effectively addresses.

HGM Grinding Mill: Engineering and Performance Excellence

Integrating German manufacturing standards with proprietary innovations, Clirik's HGM series delivers unparalleled performance:

Key Technical Specifications

- Capacity: 0.5-45 t/h

- Finished Size: 100-5μm (adjustable from 150 to 2500 mesh)

- Power Consumption: 30% lower than ball mills

- Noise Level: <80 dB(A)

Core Advantages

- Triple Grinding Zones – Hammer crushing, roller compaction, and ring abrasion ensure gradual size reduction.

- Intelligent Classification – LHA turbine classifiers achieve 99.9% screening accuracy through AI-driven speed modulation.

- Eco-Friendly Design – Pulse dust collectors maintain emission levels below 10mg/m³, exceeding EU standards.

- Low Maintenance – Modular assembly enables roller replacement within 4 hours, compared to 2 days for conventional mills.

Operational Workflow

- Raw gypsum is fed into the system via a vibrating feeder.

- Multi-stage grinding occurs through overlapping compression zones.

- Dynamic classification separates particles based on aerodynamic properties.

- Cyclone collection and silo packaging complete the process.

Why Global Producers Opt for the HGM Mill

Clirik's R&D team has further enhanced the mill with gypsum-specific configurations:

- Corrosion-resistant alloy rollers for humid crude ore

- Anti-static coatings to prevent material adhesion

- Moisture control grinding chambers with less than 1% H₂O retention

Availability and Customization

lirik offers free material testing and 24/7 technical support through its global network. The HGM series is available in 15 models with capacities ranging from 0.5t/h to 45t/h, suitable for processing natural gypsum, FGD gypsum, and phosphogypsum.