In the dynamic realm of industrial material processing, the demand for ultrafine powders has surged across various sectors, driven by the need for enhanced product performance and sustainability. Clirik's HGM Grinding Mill has emerged as a trailblazer, offering a comprehensive and innovative solution for ultrafine carbon black grinding that not only meets but also exceeds the stringent requirements of modern industries.

Innovative and Efficient Grinding Process

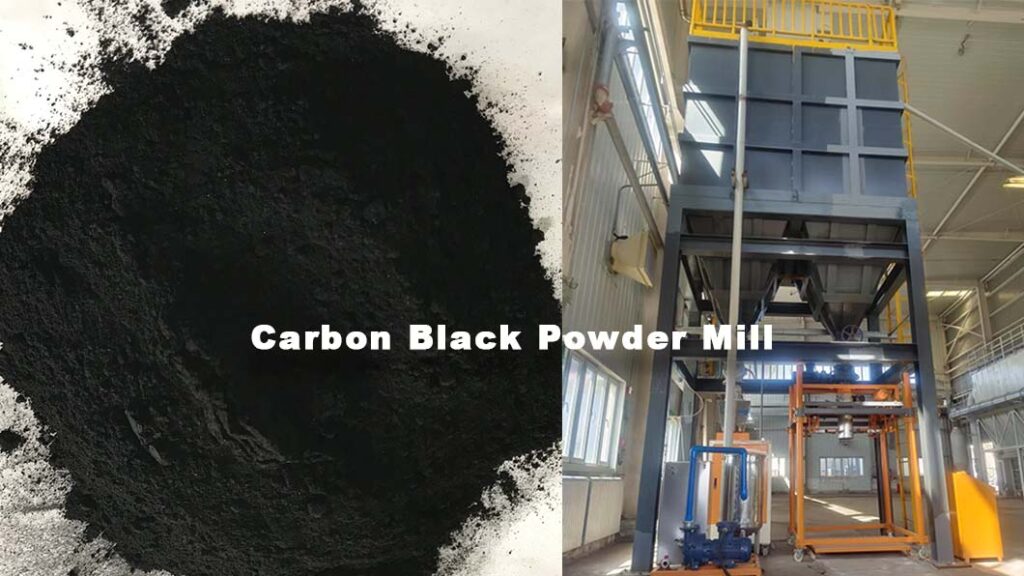

The HGM Mill is meticulously engineered to convert coarse carbon black into ultrafine powder with exceptional consistency and quality. The process begins with the initial crushing of large carbon black chunks into smaller pieces using a hammer crusher. These smaller pieces are then transported to a storage hopper via an elevator. A vibrating feeder ensures even distribution of the material onto the upper distribution plate of the turntable. As the mill operates, the grinding rollers roll within the ring channels, driven by the turntable through pins. The material undergoes multiple stages of grinding, including impact, rolling, and abrasion, ensuring thorough crushing and grinding into fine powder.

The high-pressure air blower plays a crucial role in this process. It carries the crushed material to the classifier, where a high-speed impeller screens the airflow. Particles that do not meet the required fineness are returned to the mill for regrinding, ensuring that only the finest powder passes through. The qualified powder is then collected in the cyclone powder collector. A small portion of the fine powder, carried by the airflow, moves to the dust cleaner, where it clings to the filter bags. These bags are periodically vibrated by high-pressure gas controlled by a pulse valve, causing the fine powder to fall down and be collected. This meticulous process ensures that the final product is of the highest quality, with consistent particle size and purity.

Advantages of Clirik's HGM Grinding Mill

Superior Efficiency: The HGM Mill achieves double the output compared to traditional grinding mills, significantly boosting productivity and reducing processing time. This efficiency is crucial for industries that require large volumes of ultrafine powder.

Durability and Low Maintenance: Constructed with high-quality, wear-resistant materials, the mill's components, such as grinding rollers and rings, have an extended lifespan. This reduces maintenance costs and downtime, ensuring continuous and reliable operation. The robust design of the HGM Mill means that it can handle heavy-duty tasks without frequent breakdowns, providing a cost-effective solution for long-term use.

Flexible Fineness Control: The mill offers unparalleled flexibility in adjusting the fineness of the final product. The particle size can be precisely controlled from 325 mesh to 3000 mesh, catering to a wide range of industrial requirements. This flexibility makes the HGM Mill suitable for various applications, from rubber reinforcement to high-precision coatings.

Eco-Friendly Operation: The HGM Mill is designed with environmental sustainability in mind. Advanced dust collection and noise reduction systems ensure minimal environmental impact, adhering to the strictest environmental standards. This not only protects the environment but also enhances workplace safety and comfort. The mill's low noise levels and minimal dust emissions make it an ideal choice for environmentally conscious industries.

Versatile Applications Across Industries

The ultrafine carbon black powder produced by the HGM Mill is highly versatile and finds extensive applications across various industries. In the rubber industry, it serves as a crucial reinforcing agent, significantly enhancing the strength and durability of rubber products. This is particularly important for the production of high-performance tires and other rubber components that require exceptional resilience. In the plastics industry, it acts as a stabilizer and filler, improving the overall quality and performance of plastic materials. The fine powder also plays a vital role in the production of high-quality toners and specialty chemicals, providing excellent color consistency and stability.

In the coatings and inks industry, the ultrafine powder provides superior adhesion and resistance to corrosion, ensuring that the final products have a long lifespan and high-quality finish. The fine powder is also used in the electronics industry, where its conductive properties make it an essential component in the production of various electronic devices. The versatility of the HGM Mill's output means that it can be tailored to meet the specific needs of each industry, making it an indispensable tool for modern manufacturing.

Market Leadership and Customer Satisfaction

Clirik's HGM Mill has garnered widespread acclaim for its exceptional performance, reliability, and user-centric design. With years of market validation, the mill has consistently received high praise from users across different industries. Clirik's commitment to continuous innovation and customer satisfaction ensures that the HGM Mill remains at the forefront of ultrafine grinding technology. The company's robust after-sales service and technical support further enhance the user experience, providing customers with peace of mind and long-term value.

Clirik's dedication to customer satisfaction is evident in its comprehensive after-sales service. The company offers extensive technical support, including installation guidance, operator training, and ongoing maintenance services. This ensures that customers can maximize the efficiency and effectiveness of their HGM Mill, reducing downtime and increasing overall productivity. Clirik's global network of service centers and technical experts means that customers can receive prompt and reliable support whenever they need it.

For industries seeking to enhance their carbon black processing capabilities, Clirik's HGM Grinding Mill is the ultimate solution. It combines cutting-edge technology with practical efficiency, making it a game-changer in the field of ultrafine grinding. The HGM Mill's superior efficiency, durability, flexibility, and eco-friendly operation make it an ideal choice for modern manufacturing. Upgrade your production with Clirik's HGM Mill and experience the future of grinding today. Embrace the power of innovation and precision with Clirik, and take your industrial processing to new heights.